HomeIndustrial Metal Detector

Industrial Metal Detector Manufacturers in Bangalore, Suppliers and Exporters in Bangalore

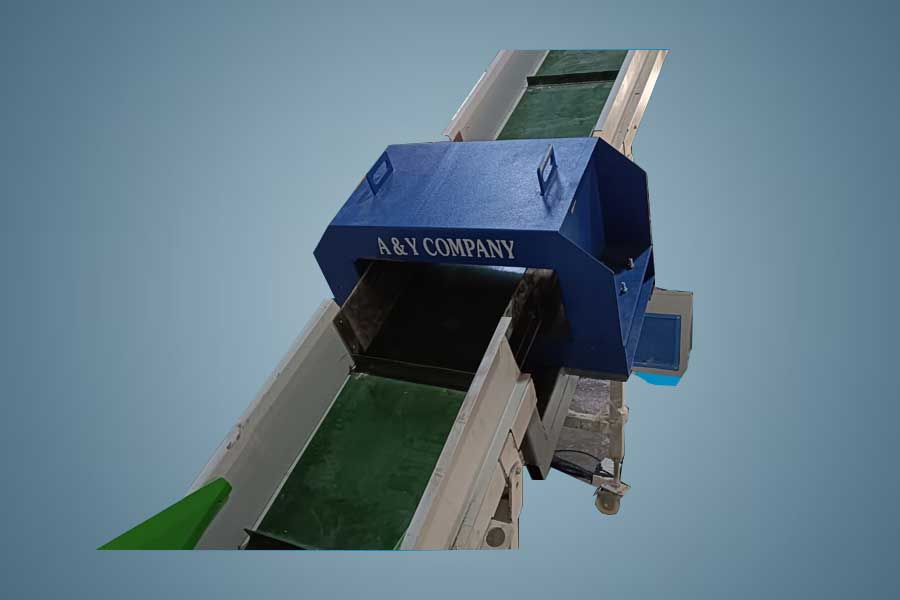

A & Y Company is a leading Industrial Metal Detector Manufacturers in Bangalore, Suppliers and Exporters in Bangalore. that is developed to identify ferrous, non-ferrous and stainless-steel impurities in harsh industrial factories. The systems are designed to precisely examine bulk materials, packaged products, and processing lines to ensure that machinery is safeguarded, there is less downtime, and that there is uniform quality of products in different industries.

Details of Industrial Metal Detector

As a leading Industrial Metal Detector Manufacturers in Bangaloreoperates on the concept of electromagnetic induction to identify the presence of metallic contaminants in raw materials, intermediate products and finished products. It is constructed in a heavy-duty and high-speed industrial setting, with a lot of emphasis on the safety of the products and the safety of the equipment.

The system comprises a transmitter coil, receiver coils, a control unit and an optional automatic rejection system. The transmitter coil produces a high-frequency electromagnetic field over the aperture of the detector. The electromagnetic field is not disturbed when a metal-free product flows through it; thus, it is balanced.

When there is a metal contaminant, ferrous, non-ferrous, or stainless steel in the product, the electromagnetic field is disrupted. This turbulence causes eddy currents in the metal particle, which creates a second magnetic field. This change is sensed by the receiver coils, which transmit a signal to the control unit.

Types of Industrial Metal Detector

As a leading Industrial Metal Detector Manufacturers in Bangalore, Suppliers and Exporters in Bangalore, we offer metal detectors of the following types:

- Pulse Induction Metal Detector

Makes use of pulse induction to identify metals in bulk material, soil or industrial products. Both ferrous and non-ferrous metal detection is effective in extreme conditions. - Carton Box Metal Detector

Checks packed cartons, boxes and packaged goods for metal contamination. Makes quality and safe products available to the final consumer. - Garment Metal Detector

Scans metal pieces in clothing, fabrics, and textiles as a way of quality assurance of their products to avoid complaints by their customers. Perfect in the clothing and textile sector. - Orange Coil Metal Detector

Intended to be used in detecting metallic impurities in bulk materials with high sensitivity orange coil technology. Commonly utilized in food, chemical and industrial settings. - Stone Crusher Metal Detector

This is used in the mining and construction industry to identify metals in the rocks and aggregates before crushing. Guarantees the safety of machinery and avoids expensive losses.

Technical Specification of Industrial Metal Detector

As Pressure Industrial Metal Detector in Bangalore, we have added below a table of technical specifications for this Detector.

| Parameter | Specification |

|---|---|

| Country of Origin | Made in India |

| Application | Bulk Material, Packaged Goods & Industrial Products Inspection |

| Operating Voltage | 230 V AC |

| Power Supply | 230 V |

| Frequency | 50 Hz |

| Detectable Metal Types | Ferrous, Non-Ferrous & Stainless Steel (All Metals) |

| Alarm Indication | LED Visual Indicator & Audible Sound Alarm |

| Maximum Scanning Aperture | 500 mm – 1200 mm (Width) × 100 mm – 500 mm (Height) (Customizable) |

| Construction Material | SS304 / SS316 Stainless Steel |

| Reject Mechanism | Pneumatic Diverter / Flap Gate / Stop Mechanism |

| Product Type | Garments, Food Powders, Granules, Chemicals, Packaged Products |

| Protection Rating | IP65 / IP66 (Washdown & Industrial Grade) |

Benefits of Industrial Metal Detectors

- Automatic Rejection System

Experts get rid of contaminated products easily with diverters, flaps or stop mechanisms that minimise human intervention. - Multi-purpose Applications in Industry

Applicable to clothes, bulk powders, granules, packaged cartons, construction aggregates and other industrial products. - Durable and Reliable

Industrial-grade construction to meet the hard operating environment, and therefore, long-lasting performance. - High Detection Sensitivity

Able to identify both ferrous and non-ferrous as well as stainless steel metals, even in high-volume materials and high-speed production lines.

Advantages of an Industrial Metal Detector

- Automatic Rejection System

When it is necessary to eliminate contaminated products within a short time, quickly, it is done with the help of flaps, diverters, and stop mechanisms, which reduces the work of humans. - Continuous and Non-Destructive Operation

Enables continuous production with no effect on the product flow, speed and integrity. - High Detection Accuracy

Identifies ferrous, non-ferrous and stainless-steel metal contaminants down to bulk or packaged goods. - Strong Construction of Industry Quality

Made of heavy-duty and long-life stainless steel or industrial-grade material to withstand the harsh conditions and heavy-duty operations.

Uses of Industrial Metal Detectors

- Garments & Textiles - It identifies metal pieces in fabrics and clothing to avoid damage to sewing machines, as well as the safety of the products.

- Food Industry - Checks bulk powders, grain, packaged foods and liquids before processing/packaging for metal contamination.

- Construction and Mining - This identifies metals in aggregates, stones and raw materials before crushing or processing to guard against machinery damage.

- Fertilizer Industry & Chemical Industry - Fertilizer Industry/Chemical Industry makes sure that powders, granules, and liquids are considered free of metallic contaminations to ensure that the products have high quality.

A & Y Company is a leading Industrial Metal Detector Manufacturers in Bangalore, Suppliers and Exporters in Bangalore. Industrial Metal Detectors provide an effective option of avoiding any metal contamination as well as equipment damage during the production. Having high sensitivity, durable construction and easy alignment with the current existing systems they help in continuity of the operations, enhanced safety and reliability of the processes in the long term.

FAQ’s

It does not have many requirements for training because there are user-friendly digital or touchscreen controls that have pre-set configurations.

Having a powerful building and powerful signal processing, it offers a high-quality continuous functionality even in a severe industrial environment.